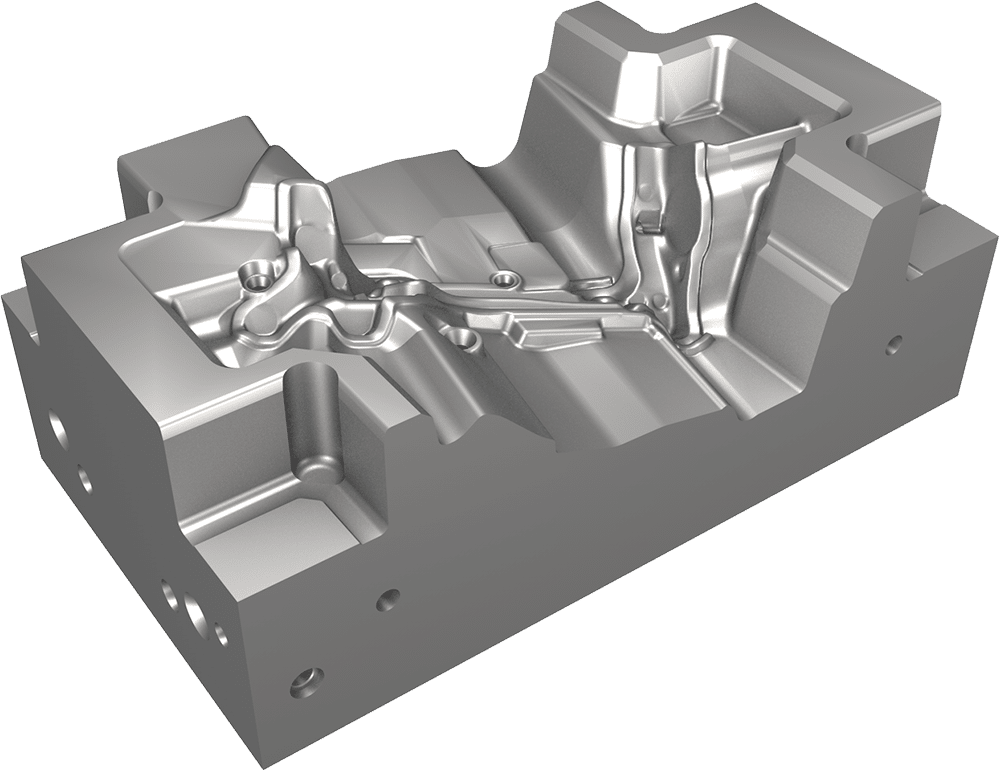

Bharat Forge Daun is your competent partner for advanced toolmaking. We use top technological quality and engineering know-how. Our forming tools set new standards in metalworking and offer innovative solutions for mechanical engineering companies.

At Bharat Forge Daun we combine tradition and innovation to offer our customers cutting-edge products in the field of forming tools. With over 50 years of experience in metal processing and in-depth specialist knowledge, we have established ourselves as a reliable partner in the industry. Our modern forming tools impress with maximum service life and precision and are designed for individual requirements in the processing of steel and aluminum.

We are aware of the challenges our customers face and respond with customized solution concepts. Our expert technical advice and our striving for the highest quality and rapid implementation make us the ideal partner for your production processes.

Bharat Forge Daun’s forming tools are versatile and play a key role in various industrial sectors. Our tools prove their efficiency and reliability particularly in vehicle construction, in the manufacture of chassis and engine parts, in the railroad technology sector and in the agricultural and construction machinery industry. Thanks to our many years of experience and continuous development, we offer tools that meet even the highest production requirements.

Our forming tools are designed for demanding hot machining to ensure maximum durability and excellent production results.

Thanks to the use of state-of-the-art design software and machine tools, our products meet all requirements in terms of service life and product quality.

Our individual solutions meet the specific requirements of various industries, from vehicle construction to agricultural and construction machinery.

By using state-of-the-art CAD/CAM systems and the latest 5-axis machining technology, we are able to produce tools that not only meet the current requirements of the industry, but also those of the future. These technologies enable us to achieve a high level of adaptability and efficiency in our production processes.

We not only develop and manufacture new products for our customers. With us, you also benefit from wear-oriented repairs for your forming and progressive tools. The durability and reliability of our tools mean a long-term investment in efficiency and productivity for our customers.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information