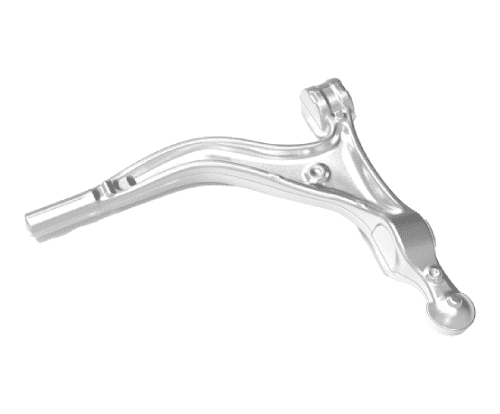

Bharat Forge Aluminiumtechnik presents the next generation of passenger car control arms, which are based on state-of-the-art technology. With their precise wheel control and stable, lightweight aluminium structure, these control arms make a decisive contribution to optimising driving behaviour and therefore ensure a top-class driving experience.

The aluminium control arm from Bharat Forge Aluminiumtechnik are an important constituent of the chassis of modern passenger cars. They connect the chassis to the wheel hub and make precise control of the wheels possible. They improve driving stability and efficiency due to their well thought-out design made from lightweight but robust aluminium. The special geometry of the control arm, including the integrated joints and sockets, provides optimum force transmission and flexibility, which leads to better steering precision and improved ride comfort.

The control arm from Bharat Forge Aluminiumtechnik represent a comprehensive solution for numerous passenger vehicles. The design of the control arm provides a stable and precise connection between the chassis and the wheel. The robust joints on the ends make flexible movement possible and contribute towards improving driving behaviour. During the development of these components, we place a great deal of emphasis on the cost-effectiveness of the material as well as precision geometry and top-quality workmanship.

The control arms from Bharat Forge Aluminiumtechnik are characterised by their high-quality aluminium construction. The design of the control arms provides a stable and precise connection between the chassis and the wheel. The robust joints on the ends make flexible movement possible and contribute towards improving driving behaviour. During the development of these components, we place a great deal of emphasis on the cost-effectiveness of the material as well as precision geometry and top-quality workmanship.

Bharat Forge Aluminiumtechnik develops its components using state-of-the-art technology. Our control arms provide:

We use high-quality aluminium and forging methods in accordance with the latest state of technology in order to guarantee that the components have outstanding strength and durability.

Our developments are aimed at minimising the weight without affecting stability and performance.

We use aluminium and efficient manufacturing processes in order to provide cost-effective solutions that reduce the overall costs of the chassis.

Benefit from our efficient forging and processing methods, which combine quality and cost-effectiveness.

Bharat Forge Aluminiumtechnik complies with the highest standards in the quality assurance of its products. Every control arm is subjected to stringent testing and simulation in order to guarantee the best possible quality. We use advanced testing procedures in order to safeguard material and workmanship quality and guarantee that our strict specifications are adhered to.

Yes, one of our strengths is how we closely collaborate with our customers during the development of components. This cooperation allows us to develop customer-specific solutions that are specially coordinated with the special requirements and performance specifications of different vehicle models. The use of this approach means that our control arms not only fulfil requirements, but also provide optimum results for any specific application area.

Bharat Forge relies on sustainable manufacturing processes. Aluminium as a material is not only efficient in production, but is also completely recyclable, which contributes to reducing our ecological footprint.

FEM calculations can be carried out upon request in order to confirm the strength of our products. These are then used to carry out detailed analysis and checking of the structural integrity and resilience of our components. This ensures that they correspond to the individual requirements and expectations of our customers.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information