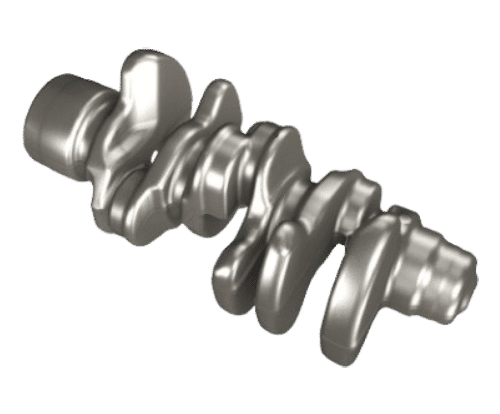

The crankshafts from Bharat Forge CDP set standards with regards to performance in the world of drive technology. They stand for top quality and are designed to fulfil technical specifications in a reliable and efficient way.

Made from high-quality steel, our crankshafts are ideal for car engines with 2 to 6 cylinders. They combine maximum strength and a long service life with a weight-optimised design, which leads to efficient force transmission and improved engine performance. The precision workmanship is the guarantee of minimal vibration and optimum performance for different engine sizes. These crankshafts provide a reliable and effective solution for numerous car models.

Crankshafts from Bharat Forge CDP are developed for car engines with 2 to 6 cylinders.

The forged crankshafts from Bharat Forge CDP are characterised by their high-quality construction and precision manufacturing. We pay special attention to material selection and geometric design in order to guarantee a high loading capacity and a long service life. Our advanced manufacturing processes guarantee excellent quality and performance capability.

During production, Bharat Forge CDP relies on innovative technologies in order to design pioneering components. Our crankshafts provide:

We use advanced manufacturing process in order to ensure that our crankshafts have a high loading capacity and a long service life.

The optimised design and the precision manufacturing provide reliable and efficient force transmission.

We use high quality yet cost-effective materials, which guarantees that our crankshafts have an optimal price/performance ratio.

We use innovative manufacturing methods to reduce production costs and increase the efficiency and quality of our manufacturing processes at the same time.

Quality has top priority at Bharat Forge CDP. Each crankshaft is subjected to strict quality controls, including specialised testing, in order to guarantee the highest standards with regard to performance and reliability. We use advanced measuring techniques and material testing in order to guarantee consistent product quality.

Bharat Forge CDP can manufacture crankshafts in a wide range of weights. For our crankshafts specifically, the unfinished part weight is between 12 kg and 25 kg. This weight range allows us to fulfil a wide range of requirements for different vehicle models and engine sizes, whereby we always ensure optimum performance and quality.

In order to guarantee the highest quality standards for our crankshafts, Bharat Forge CDP relies on comprehensive and strict monitoring procedures. Each crankshaft is subjected to a series of quality checks that are specially aimed at guaranteeing the safety and reliability of the product. The main focus of these checks are the magnetic particle crack test and the alternating voltage test.

The magnetic particle crack test is a decisive procedure for detecting irregularities on or close to the surface in the crankshafts. This method is very effective for detecting cracks and other structural defects that could affect the functionality or safety of the product.

In addition to this, we also carry out alternating current testing. These tests are very important for discovering internal irregularities that can occur during the manufacturing process. By means of these tests, we ensure that each crankshaft corresponds to our high quality standards before it leaves our factory.

These strict testing procedures are an integral part of our commitment to providing our customers with maximum product quality. They guarantee that every crankshaft from Bharat Forge CDP fulfils expectations and therefore provide unparalleled reliability and performance capability.

Yes, Bharat Forge CDP and its production facilities currently concentrate on manufacturing crankshafts specifically for passenger vehicles.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information