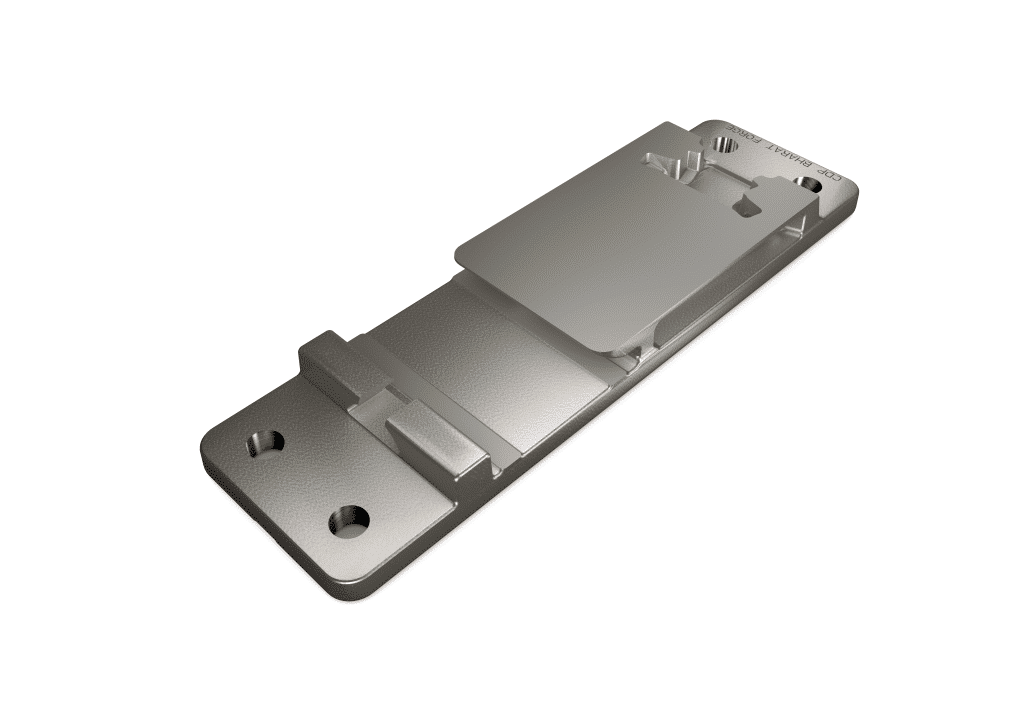

Sliding chair plates from CDP Railsystems can be manufactured in either cast or welded form and are particularly suitable in combination with our switch rollers.

CDP Railsystems has a wide range of sliding chair plates when it comes to field of switch rollers. They fulfil the highest of demands in point technology in terms of both material characteristics and technical processing. In addition to our standard products, we also develop individual and tailor-made solutions. This means that all common systems are available for inner stock rail tensioning. As well as Pandrol e-Clip, SKL / KPO is also available as a fastening system for the stock rail outer side.

At CDP Railsystems, sliding chair plates are usually manufactured using the spheroidal graphite cast iron casting process. Subsequent mechanical processing provide the final touch. When this takes place, all projections from the casting procedure are removed and the sliding surfaces are then milled during machining. In addition to purely cast parts, we also supply welded structures as a solution for our customers. These are mainly used in special constructions and are suitable in small quantities.

Sliding chair plates can also be given an NiCr or molybdenum coating upon request. This improves the sliding characteristics of the surface and reduces the need for lubricants. This does not only reduces maintenance and servicing costs, but also reduces susceptibility to failures, thus ensuring that the points operate reliably.

Sliding chair plates manufactured by CDP Railsystems are particularly suitable in combination with our switch rollers. Here too, we supply standard parts for all common rail profiles and develop individual solutions that are tailored to your technical requirements. Through the combined use of a Sliding chair plate and a switch roller, the force that is required to change the points is reduced considerably. Furthermore, the sliding chair plate does not require lubrication.

Your capable partner for points, locking systems and railway infrastructure

We would be pleased to assist you personally with any concerns you may have. We are available Monday-Friday from 9 am to 4 pm, and you can contact us either by phone, email or via our contact form.

Some point systems do not use switch rollers. In this case, the sliding chair plates alone is used as the contact surface for the stock rail when the points are being changed. In order to guarantee reliable operation, the sliding chair plates must therefore be lubricated. An NiCr or molybdenum coating improves the sliding characteristics and reduces the need for lubricant. This saves money on point servicing and maintenance and reduces the frequency of faults.

The Pandrol e-Clip provides good vibration damping and is resistant to loosening caused by rail traffic vibrations. Tensioning clamps (SKL) and clamping plates (KPO) are characterised by their high clamping force. They are particularly suited to high loads and are often used in areas with heavy traffic or in situations with special rail mounting requirements. The choice between these two systems therefore depends on the specific requirements of the rail infrastructure, the load acting upon the rail and the maintenance and installation requirements.

A special installation tool is required to install the SSB bracket. Exact instructions for the tool that is required and for installation can be found in the installation instructions. These are delivered to the customer by CDP Railsystems.

Yes, we also have a wide range of integrated switch rollers with a modified sliding chair plates . This system is particularly characterised by its low-maintenance operation, since the slide chair does not have to be lubricated. A selection of standard components can be found in our product overview, which you can download free of charge.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information