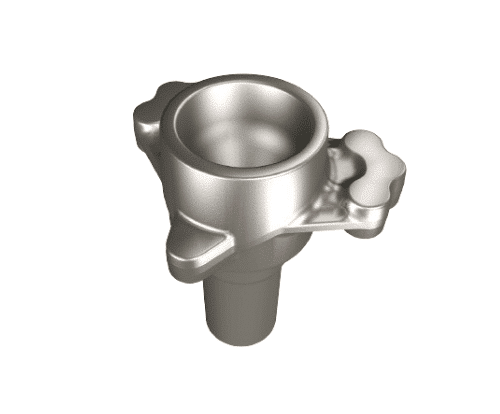

The axle journals from Bharat Forge CDP give truck chassis a modern technical configuration. They are decisive for connecting wheels and vehicle axes and therefore make an important contribution to the stability of the vehicle.

Our axle journals are made from high-strength steel in order to cope with the high stress levels to which they are subjected. They have been meticulously designed in order to guarantee a perfect fit, which plays an important part in the overall safety and performance of the vehicle. The precision manufacturing of each axle journal does not only guarantee an optimum fit, but also maximum functional capability and a long service life.

The optimised design of the axle journals ensures that they can effectively absorb and transmit force without losing stability. This is particularly important as the axle journals are a key component in the steering and suspension system of the vehicle. They must therefore not only support the weight, but also make precise steering movements possible. By using high-quality materials and advanced manufacturing techniques, we ensure that our products have a long service life and also function reliably under harsh operating conditions.

Overall, our axle journals provide an excellent combination of strength, weight optimisation and reliability. They are the result of constant endeavours to develop innovative and high-quality solution for vehicle engineering. The goal: to maximise the safety, performance and efficiency of commercial vehicles.

Axle journals from Bharat Forge CDP are specially designed for the trailers of commercial vehicles and provide a high degree of reliability under a wide range of operating conditions.

Bharat Forge CDP produces components based on the latest state of the art. Our axle journals provide the following:

By means of highly-developed manufacturing processes, we guarantee that our products have outstanding durability and loading capacity.

Targeted material selection and design make effective weight reduction possible without having a negative effect on load-bearing capacity.

Efficient production methods reduce costs while ensuring quality remains high.

Our advanced manufacturing techniques do not only reduce costs, but also improve efficiency and quality.

Bharat Forge CDP is committed to the highest quality standards in product testing. Our axle journals are subjected to meticulous testing, including magnetic particle crack tests and alternating voltage tests. This is how we ensure that the quality is top class. We also use ultrasound tests to ensure that each material that is used corresponds to our exact specifications.

AFP steels (Advanced High-Strength Steels) are among the high-strength steel classes and are characterised by their excellent mechanical properties. They are mainly used in the automotive industry for increasing the safety, and also the efficiency, of vehicles. These types of steel boast an optimum combination of strength, ductility and malleability.

They are designed to absorb a great deal of energy in the event of an accident, which provides additional safety. AFP steels also make lighter vehicle structures possible, which reduces the overall weight of the vehicle and therefore improves fuel consumption efficiency.

AFP steels have different strength classes, and their development is based on advanced alloying procedures and heat treatment techniques in order to achieve optimum mechanical properties. These types of steel are a central constituent in modern vehicle manufacturing and make an important contribution to increasing vehicle performance, safety and environmental compatibility.

Our axle journals are manufactured with an unfinished part weight of between 12 kg and 18 kg. This weight range allows us to provide customised solutions for different vehicle models and requirements, whereby we always ensure optimum quality and performance.

Bharat Forge CDP uses the highest quality standards in the manufacture of its axle journals. We achieve this by means of detailed and strict quality checks that are aimed at safeguarding product integrity and reliability. Our axle journals undergo a comprehensive range of tests, including magnetic particle crack testing and alternating current tests, in order to identify surface defects and concealed defects. This testing is decisive in identifying structural defects that could affect the functionality or safety of the products.

The use of the alternating current test is an important step for discovering internal irregularities that can occur during the production process. These meticulous testing processes ensure that every axle journal fulfils the high quality standards we have set before it leaves the factory.

These strict testing processes form the heart of our quality promise to our customers. They ensure that every axle journal from Bharat Forge CDP fulfils all requirements and provides excellent reliability and performance capability.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information