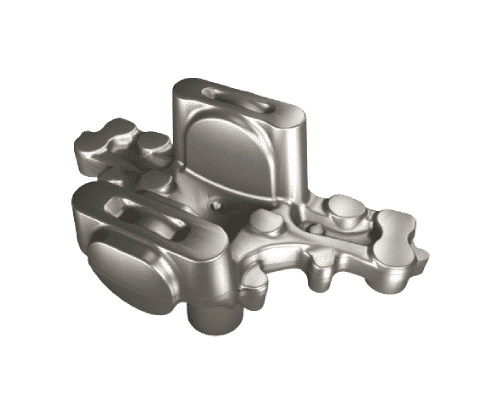

The steering knuckles from Bharat Forge CDP represent the latest state of the art for lorry chassis. They make efficient steering movements possible thanks to their swivelling wheel carriers at the ends of rigid axles or individual wheel suspensions.

Steering knuckles are divided into 2 areas: the spindle and the head. The spindle is used to hold the wheel bearings and the central wheel nut at the end of the spindle. The spindle is subjected to a considerable amount of lateral force in the vicinity of the wheel contact line due to the weight of the vehicle. This force is present as an alternating load that is subject to extremely large fluctuations while driving. The lateral force results in a bending load that increases towards the head. This is also subject to large fluctuations while driving.

The head represents the connection to the vehicle or to the different wheel steering levers with its different interfaces (screw connections) to the rigid axes or with individual wheel suspensions to the different wheel control arms. It also has connections for the brake caliper with disk brakes or screw-on locations for connecting drum brakes.

In order to account for these tremendous requirements, the steering knuckles at Bharat Forge CDP are optimised with regard to material characteristics, design and workmanship.

Steering knuckles from Bharat Forge CDP are designed for trucks and can be equipped with an integrated steering arm.

The steering knuckles from Bharat Forge CDP are characterised by their high-quality construction made from two main components consisting of: the spindle and the head. The spindle is designed to hold the wheel bearings and deals with the challenges of lateral force and bending loads thanks to its robust design. The head of the steering knuckle forms the interface to the wheel control arms and provides connections for brake systems at the same time. During the development of these components, a great deal of emphasis is put on material characteristics, the precision geometry and the top-quality workmanship.

Bharat Forge CDP develops its components using state-of-the-art technology. Our steering knuckles provide:

We guarantee unparalleled strength under alternating loads by means of drop forging and specialised heat treatment processes.

Our FEM calculations make target weight reductions possible without affecting stability.

By using AFP steels, we do not only reduce the costs, but also the CO2 footprint of our products.

Our advanced manufacturing techniques do not only reduce costs, but also improve efficiency and quality.

Bharat Forge CDP complies with the highest standards in the quality assurance of its products. Every steering knuckle is subjected to stringent testing and simulation in order to guarantee the best possible quality. This involves using magnetic particle crack tests and alternating current tests, while our ultrasound tests ensure that each material corresponds with our strict specifications.

AFP steels (Advanced High-Strength Steels) are a class of high strength steels that are known for their excellent mechanical properties. They are mainly used in the automotive industry in order to improve the safety and efficiency of vehicles. AFP steels provide an excellent combination of strength, ductility and malleability.

These steels are designed to provide a high degree of energy absorption in the event of accidents. They also make lighter vehicle constructions possible, which leads to a reduction of the overall weight and therefore improves fuel consumption efficiency.

AFP steels can be manufactured in different strength classes. The development of these steels includes advanced alloying techniques and heat treatment processes in order to achieve the required mechanical properties. They are an important constituent of modern vehicle constructions and make an important contribution to improving the performance, safety and sustainability of vehicles.

At Bharat Forge CDP, we can develop and manufacture steering knuckles within a wide range of weights in order to fulfil various customer requirements. Our range of products includes steering knuckles that have an unfinished part weight of 30 kg to 60 kg. This weight class flexibility class allows us to offer customised solutions for numerous commercial vehicles, whereby we always maintain a balance between performance capability and efficiency.

In order to guarantee the highest quality standards for our steering knuckles, Bharat Forge CDP puts a considerable amount of emphasis on strict and comprehensive monitoring procedures. Each of our steering knuckles is subjected to a series of quality checks that are specially aimed at guaranteeing the integrity and reliability of the product. The main focus of these checks are the magnetic particle crack test and the alternating voltage test.

The magnetic particle crack test is a critical procedure that allows us to identify irregularities on or just below the surface of the steering knuckles. This method is very effective for detecting cracks and other structural defects that could affect the performance or safety of the product.

In addition to this, we also use alternating current testing. These tests are decisive for discovering internal irregularities that can occur during the manufacturing process. By means of these tests, we ensure that each steering knuckle corresponds to our high quality standards before it leaves our factory.

The strict testing procedures are an integral part of our quality promise to our customers. They guarantee that every steering knuckle from Bharat Forge CDP fulfils all expectations, and therefore provides top quality reliability and performance.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information