Safety and reliability are the core features of Switch locking systems. By keeping a firm grip on the point blades, they ensure problem-free railway operations and contribute to cost efficiency in the maintenance and servicing area.

Low-maintenance turnout locks are crucial for a reliable and economical rail infrastructure.

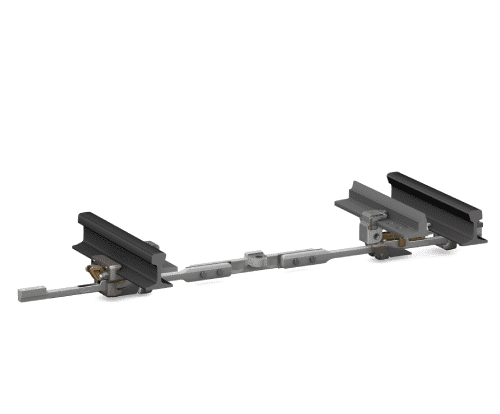

The low-maintenance claw log devices from CDP Rail Systems represent the state of the art for locking systems. They can be used to reduce railway point servicing costs over the long term. Current designs include the WKV, the BFL and the EVZ.

The EVZ claw log devices is a new development from CDP Rail Systems on behalf of Deutsche Bahn AG. It can be used to smoothly and easily replace old generations of different claw log devices, leading to a considerable amount of standardisation in point technology. The EVZ automatically adapts to temperature-dependent length changes of +/- 35 mm. The use of materials with special sliding properties means that the sliding surfaces only need to be lightly re-greased during point inspections. A special feature of the EVZ is the clamp, which can be adjusted manually using an eccentric. This eliminates the need for the grinding-in that is required with conventional locks. All of the main components are drop-forged, meaning that they meet the highest safety requirements.

As a general rule, we can guarantee delivery of our claw log devices within 3 weeks. In consultation with CDP Railsystems, we can also guarantee shorter delivery times.

In rail and switch technology, the claw log devices is of crucial importance when it comes to the safety and reliability of rail traffic. As an integral component of points, they enable trains to switch safely from one track to another. Their main task is to fix the moving parts of a point in their intended end position.

This ensures that trains can roll over the point without any issues. The robust material properties of the switch lock and a firm anchoring also prevent external forces caused by train traffic or environmental influences from unintentionally changing the switch position. The modern design of our clamp locks guarantees a long service life and ensures that they will function reliably over a long period of time and require little maintenance. This not only contributes to high availability of the rail network & infrastructure, but also significantly reduces operating costs.

Your capable partner for points, locking systems and railway infrastructure

We would be pleased to assist you personally with any concerns you may have. We are available Monday-Friday from 9 am to 4 pm, and you can contact us either by phone, email or via our contact form.

Yes, CDP Railsystems has developed its own training programme especially for the EVZ claw log devices. We offer this training to customers directly on site. During this training programme, we not only provide employees with the expert knowledge they need regarding the design and functioning of our claw log devices. Correct installation in the signal box is also trained in a practical exercise. At the end of the training course, all participants will have the necessary experience to avoid errors during the installation process and maintenance operations in the future.

The training program for low-maintenance turnout locks is divided into a theoretical and a practical part, each lasting approx. 2-3 hours. In the theoretical part, we provide fundamental expert knowledge about the structure and functioning of the claw log device as well as necessary servicing measures. In the practical part, we then provide step-by-step training on how to properly assemble the stock rail and switch rail. All participants will receive a certificate at the end of the programme by request.

The standardised lock for switch rollers can be assembled and adjusted very quickly compared to other locking systems. The EVZ was specially developed by CDP Railsystems on behalf of Deutsche Bahn AG and has been part of the standard interlocking system within the DB AG network since 2016. It allows us to guarantee a very high degree of availability regarding our locks, which also makes it much easier to replace wearing parts. The EVZ and EVH have approval from the Federal Railway Authority (Eisenbahn-Bundesamt, or EBA).

The following information is relevant for the correct design of a turnout lock – e.g. clamp lock turnout:

There are various types of switch fasteners, such as clip fasteners, slide fasteners, clamp fasteners or spring latch fasteners – each with specific properties.

If you have any further questions regarding the design of a turnout lock, you can consult our contact persons at any time or read our blog.

With the standard EVZ, the values for the switch impact and the overlap are predefined by the selected lock type. Manual adjustment is not possible in this instance. However, it is different with the EVZ with Unibar, which was developed and patented by CDP Railsystems. Both values can be set manually in this case.

All the tools required to install a turnout lock are specified in our instructions. However, CDP Railsystems has developed a special EVZ toolkit so that you are optimally prepared for every installation in future without having to search for the right tool beforehand. It contains a complete tool set that can be used for all types of locks. The EVZ Toolkit can be ordered from us at any time upon request.

There are different types of turnout locks, which are selected depending on the type of turnout and operating conditions. These include, among others:

Soft tip closure – classic locking mechanism at the tip of the tongue

Soft clamp closure – tongue is pressed against the cheek piece by the clamp

Latch lock switch – mechanical locking via latch system

Other variants such as slide fasteners, clamp fasteners or spring latch fasteners

The choice of the right turnout lock depends, among other things, on the travel, rail profile and drive type. Further information can be found in the blog.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information