Bharat Forge Daun stands for the highest level of manufacturing expertise and state-of-the-art CNC technologies.

In the field of mechanical processing, we offer you precise CNC milling, complemented by our experience in tool and fixture construction.

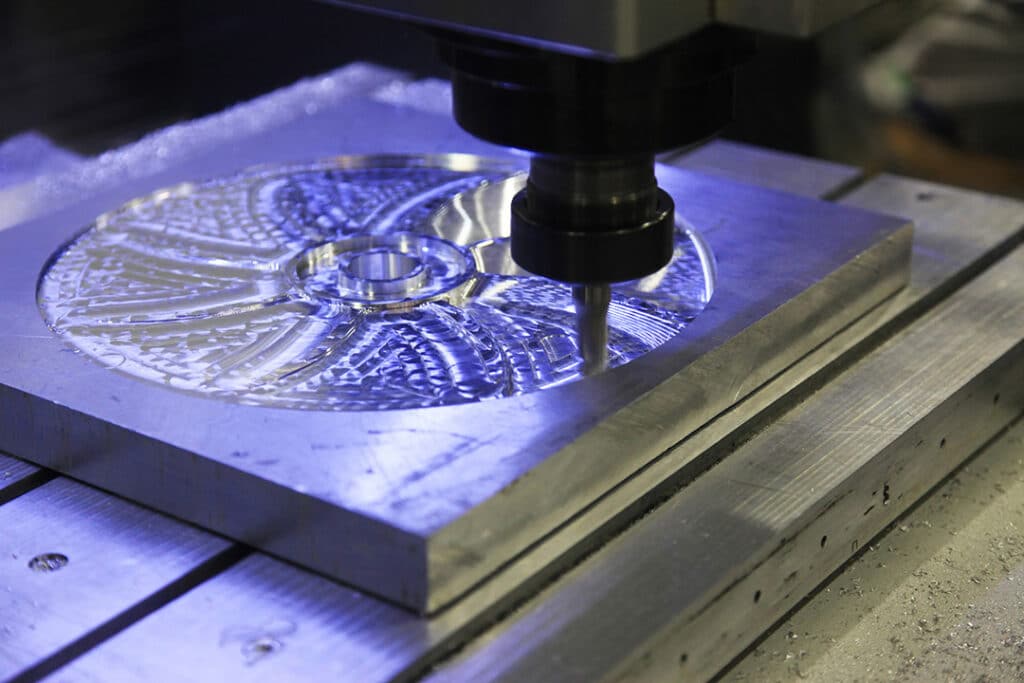

CNC milling is a modern manufacturing process in which workpieces made of metal, plastic or other materials are precisely machined using rotating cutting tools. Unlike turning, the component remains firmly clamped while the tool moves along several axes, removing material layer by layer.

All parameters such as feed rate, speed and tool paths are precisely controlled via a CNC program. This results in complex shapes, precise contours or defined surfaces – from prototypes to series components.

The process is used wherever high dimensional accuracy, tight tolerances and repeatable quality are crucial – for example in mechanical engineering, the automotive industry, medical technology or special plant construction.

At Bharat Forge Daun, CNC milling is a central process in CNC machining and combines flexibility with maximum precision.

Our CNC milling machines are specially designed for the precise machining of steel and aluminum. Thanks to automated feeds, precisely controlled spindle speeds and the use of multiple axes, even complex geometries can be realized with high dimensional accuracy.

Thanks to stable processes, we achieve tight tolerances, clean contours and consistent surface quality – regardless of whether we are dealing with individual parts, prototypes or series production.

With this technological foundation, CNC milling is a central component of our CNC machining and provides the basis for precise components in a wide range of industries, from the automotive industry to mechanical engineering.

CNC milling is a modern manufacturing process in which workpieces made of metal, plastic or other materials are precisely machined using rotating cutting tools. Unlike turning, the component remains firmly clamped while the tool moves along several axes, removing material layer by layer.

All parameters such as feed rate, speed and tool paths are precisely controlled via a CNC program. This results in complex shapes, precise contours or defined surfaces – from prototypes to series components.

The process is used wherever high dimensional accuracy, tight tolerances and repeatable quality are crucial – for example in mechanical engineering, the automotive industry, medical technology or special plant construction.

At Bharat Forge Daun, CNC milling is a central process in CNC machining and combines flexibility with maximum precision.

Our CNC milling machines are specially designed for the precise machining of steel and aluminum. Thanks to automated feeds, precisely controlled spindle speeds and the use of multiple axes, even complex geometries can be realized with high dimensional accuracy.

Thanks to stable processes, we achieve tight tolerances, clean contours and consistent surface quality – regardless of whether we are dealing with individual parts, prototypes or series production.

With this technological foundation, CNC milling is a central component of our CNC machining and provides the basis for precise components in a wide range of industries, from the automotive industry to mechanical engineering.

At Bharat Forge Daun, you receive CNC milled parts that combine precision, stability and cost-effectiveness. Our many years of experience in the machining of steel and aluminum and our modern machinery make us a reliable partner for demanding production projects.

We combine a high level of vertical integration with efficient processes and tested quality. This results in milled parts that are reliably manufactured even with tight tolerances and complex geometries – on time and reproducible.

At Bharat Forge Daun, you receive CNC milled parts that combine precision, stability and cost-effectiveness. Our many years of experience in the machining of steel and aluminum and our modern machinery make us a reliable partner for demanding production projects.

We combine a high level of vertical integration with efficient processes and tested quality. This results in milled parts that are reliably manufactured even with tight tolerances and complex geometries – on time and reproducible.

CNC milling enables extremely high precision. Using modern machines, we achieve tight tolerances down to hundredths of a millimeter. This results in dimensionally accurate components made of steel and aluminum that meet even the highest requirements in industry and mechanical engineering.

Common processes include 3-axis CNC milling for standard geometries and 5-axis CNC milling for particularly complex shapes and free-form surfaces. By using multiple axes, workpieces can be efficiently produced in a single operation – ideal for prototypes and series.

In CNC turning, the workpiece rotates while a tool removes material. It is suitable for round components such as shafts or sleeves. During CNC milling, the workpiece remains fixed and the cutting tools move along the X, Y and Z axes. This allows complex contours, surfaces and drill holes to be produced with precision.

CNC milled parts are components that are programmed using a CAD file and manufactured on a CNC machine. They range from prototypes to individual items and series and are used in numerous industries.

Milled parts can be additionally processed – for example by surface treatments such as engraving and polishing. This improves the appearance, function and durability of the production parts.

The costs depend on factors such as material (e.g. steel or aluminum), component size, tolerances and quantity. We prepare a transparent calculation for every inquiry, including delivery time and a detailed quotation.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information