Bharat Forge Daun stands for manufacturing expertise, quality and state-of-the-art technologies.

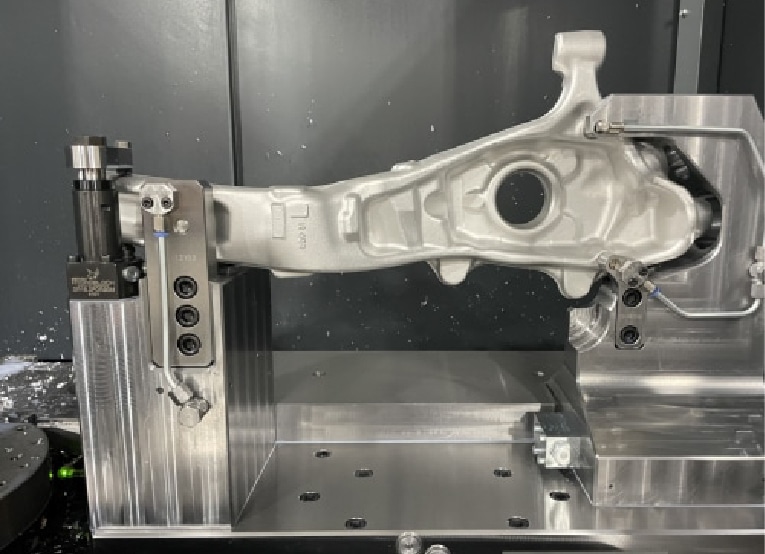

In the field of mechanical processing, we develop and produce precise fixtures for the automotive industry and mechanical engineering – from welding fixtures to assembly fixtures.

Fixture construction involves the development and manufacture of precise aids that make production processes more efficient, reliable and repeatable. Jigs and fixtures are used to secure workpieces during processing, assembly or during welding and reliably fix them in place.

With modern construction technology and our experience, we create solutions that are precisely tailored to our customers’ requirements – from clamping fixtures and welding fixtures to assembly fixtures. Each fixture is developed specifically for the intended use.

Fixture construction is in demand in all areas where high precision, stable processes and consistent quality are crucial – whether in the automotive industry or in mechanical engineering.

At Bharat Forge Daun fixture construction forms the basis for efficient manufacturing and reliable production processes.

Our fixture construction department specializes in the precise production of fixtures for steel and aluminium components. Using state-of-the-art technologies, sophisticated design and automated processes, we develop solutions that are precisely tailored to our customers’ requirements.

Whether welding fixtures, assembly fixtures or clamping fixtures – every design is created with maximum dimensional accuracy and is tailored to stable production workflows. We place particular emphasis on flexibility in order to be able to reliably support prototypes, small series and series production.

This technological basis makes our fixture construction a decisive factor for efficient production processes and precise results in the automotive industry, in mechanical engineering and in other areas of production technology.

Fixture construction involves the development and manufacture of precise aids that make production processes more efficient, safer and repeatable. Fixtures are used to precisely position and reliably fix workpieces during machining, assembly or welding.

With modern construction technology and our experience, we create solutions that are precisely tailored to our customers’ requirements – from clamping fixtures and welding fixtures to assembly fixtures. Each fixture is developed specifically for the intended use.

Fixture construction is in demand in all areas where high precision, stable processes and consistent quality are crucial – whether in the automotive industry or in mechanical engineering.

At Bharat Forge Daun, fixture construction forms the basis for efficient manufacturing and reliable production processes.

Our fixture construction department specializes in the precise production of fixtures for steel and aluminium components. Using state-of-the-art technologies, sophisticated design and automated processes, we develop solutions that are precisely tailored to our customers’ requirements.

Whether welding fixtures, assembly fixtures or clamping fixtures – every design is created with maximum dimensional accuracy and is tailored to stable production workflows. We place particular emphasis on flexibility in order to be able to reliably support prototypes, small series and series production.

This technological basis makes our fixture construction a decisive factor for efficient production processes and precise results in the automotive industry, in mechanical engineering and in other areas of production technology.

At Bharat Forge Daun, you get fixtures that combine precision, stability and efficiency in production. Our experience in fixture construction for the automotive and mechanical engineering industries and our close links with toolmaking and CNC machining make us a strong partner for demanding projects.

We develop solutions with a high level of vertical integration and tested quality – from clamping fixtures to welding fixtures and assembly fixtures. This results in fixtures that function reliably even with complex requirements and tight tolerances and ensure smooth production processes.

At Bharat Forge Daun, you receive fixtures that combine precision, stability and efficiency in production. Our experience in fixture construction for the automotive and mechanical engineering industries and our close links with toolmaking and CNC machining make us a strong partner for demanding projects.

We develop solutions with a high level of vertical integration and tested quality – from clamping fixtures to welding fixtures and assembly fixtures. This results in fixtures that function reliably even with complex requirements and tight tolerances and ensure smooth production processes.

Alignment refers to the precise positioning and adjustment of workpieces within a fixture so that the production steps can be implemented exactly. Correct alignment is crucial for the dimensional accuracy, quality and efficiency of production processes. With our experience, we offer suitable solutions that reliably position your workpieces and optimize the production process. Especially in conjunction with CNC turning and CNC milling ensure precise alignment for maximum repeat accuracy and efficiency.

A clamping device is a tool that holds workpieces securely in place while machining or assembly processes are carried out. It enables repeatable positioning and stable production processes. As an experienced partner in fixture construction, we develop clamping fixtures individually for your requirements, whether prototypes, small series or series production. Clamping fixtures are particularly useful for CNC drilling and milling parts to ensure precise machining results.

Equipment in fixture construction includes all aids that support the production process. These include, for example, welding devices, assembly devices, positioning aids or devices for CNC machining. They form the basis for efficient processes and precise results. With the right equipment, both small batches and series production can be reliably realized.

Today, the term “production technician for fixture and tool making” or “CNC and fixture specialist” is usually used. These experts combine traditional craftsmanship with modern technologies and develop customized devices and tools that make production processes stable and efficient. As a reliable partner, we support our customers from planning to commissioning.

The position of the device within the production process determines efficiency and accessibility for workpieces and operating personnel. At the same time, the costs for materials, production and maintenance have a direct impact on the profitability of a project. Procuring the right components and tools is also crucial: only if all parts are available on time and in the required quality can deadlines be met and production processes carried out reliably. As a partner in fixture construction, we take these factors into account at an early stage in order to deliver customized and cost-efficient solutions. In conjunction with CNC turning, CNC milling and weldingcan be used to realize consistent, efficient production processes.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information